Local raw materials

And in-house production

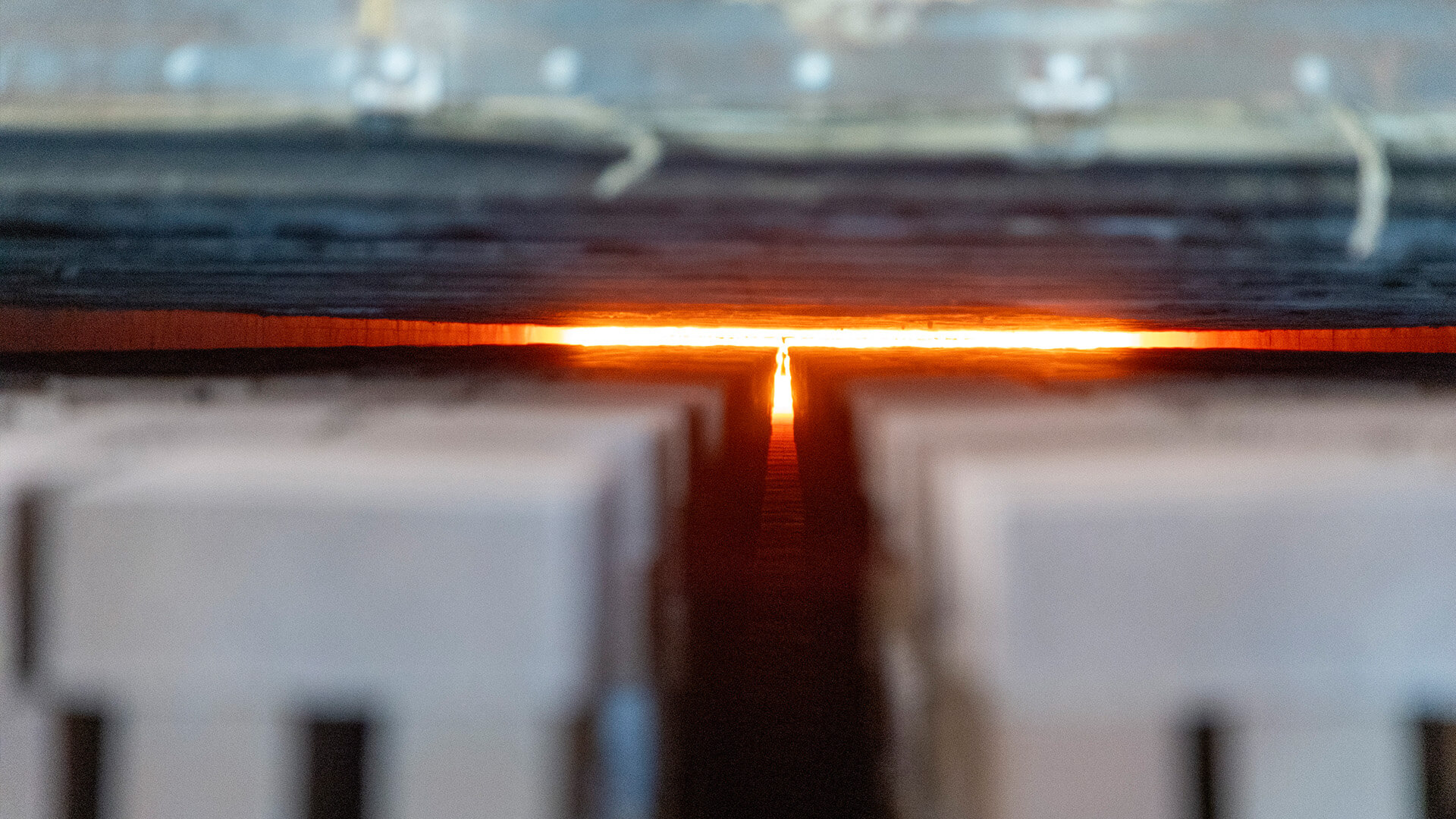

We pride ourselves on working with local clay and managing the entire production process in-house.

Discover how our passion for craftsmanship, commitment to sustainability and the application of extrusion technology result in facing bricks of exceptional quality, with a consistent shape, colour and texture.